Making Every

Move Intelligent

Revolutionizing dock, warehouse & line automation with smart sensing, <br>real-time logic, and seamless ERP/WMS integration.

OUR OFFERINgS

Automation Solutions

Comprehensive automation portfolio for modern warehouses

Industries We Serve

E-commerce, 3PL/4PL, FMCG, Retail, Manufacturing

Variants We Offer

- Semi-Automated Dock

- Modular Dock System

- Fully Automated Dock

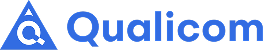

Dock Automation

Smart automation for faster, error-free truck loading/unloading with integrated scanners, weighing, conveyors, and PLC/SCADA control—fully synced with your ERP/WMS.

Our Detailed Deliverables

- Barcode/RFID scanning

- Dynamic weighing systems

- Roller/belt conveyors

- PLC & SCADA control panels

- Safety gates & sensors

- ERP/WMS integration

How It Works

- Truck docks

- Safety validation

- Conveyors extend

- Items scanned & weighed

- System verifies orders

- Data syncs to ERP/WMS

- Dispatch triggered

Key Customer Benefits

- 60% faster turnaround

- Zero manual errors

- Real-time visibility

- Smooth ERP/WMS sync

- Enhanced safety

Industries We Serve

E-commerce, Parcel & Courier, 3PL/4PL, Retail Distribution, Postal Services

Variants We Offer

- Linear Sorter – Straight-line with side diverters

- Loop Sorter – Circular, high throughput

- Cross-Belt Sorter – Gentle handling for fragile items

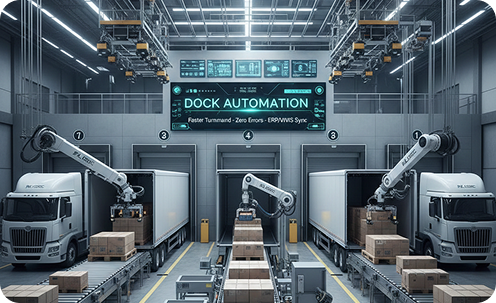

Sorting Solutions

High-speed, precision systems for parcels, cartons, and totes using vision technology, scanners, conveyors, and intelligent diverters—delivering accurate, high-volume routing with near-zero errors.

Our Detailed Deliverables

- Vision & barcode scanning systems

- High-speed conveyor lines

- Intelligent diverters for precise routing

- Sorting logic controller

- Reject/exception handling stations

- WMS integration for order management

How It Works

- Items inducted into the system

- Vision/scanners identify and classify

- Controller assigns correct destination

- Conveyors move items to divert points

- Diverters route items to correct lanes

- Exceptions sent to manual station

- System logs data for full traceability

Key Customer Benefits

- Sort up to 10,000+ items/hour

- 99.9%+ accuracy

- Flexible, reconfigurable layout

- Scalable lane/zone expansion

- AI-optimized routing

Industries We Serve

E-commerce, 3PL/4PL, Urban Fulfillment, Fast Fashion, Quick Commerce

Variants We Offer

- Compact Zigzag – 2-level, 20–30 destinations

- Standard Zigzag – 3-level, 40–60 destinations

- High-Capacity Zigzag – 4+ levels, 80+ destinations

Zig Zag Sorter

Compact, high-throughput sorting system with intelligent diverters—designed for facilities needing maximum performance in minimal floor space.

Our Detailed Deliverables

- Compact zigzag sorting frame

- High-speed barcode/vision scanners

- Pop-up diverters for precise routing

- Multi-level chute system

- Smart flow-control controllers

- Modular expansion design

How It Works

- Items inducted at high speed

- Scanners capture destination data

- System selects optimal zigzag path

- Diverters guide items through turns

- Items routed to multi-level chutes

- Collection bins receive sorted items

- Full-bin alerts triggered automatically

Key Customer Benefits

- 40% floor-space savings

- 8,000+ items/hour throughput

- Lower CAPEX vs conventional sorters

- Modular lane expansion

- 99.8%+ sorting accuracy

Industries We Serve

3PL/4PL, Manufacturing, Retail Distribution, Pharmaceuticals, Automotive Parts

Variants We Offer

- 2-Floor System – Ground to mezzanine

- Multi-Floor System – 3–5 floor connectivity

- High-Rise VLM – Up to 16m for high-density storage

Vertical Lift Systems

Automated vertical movement for pallets, totes, and cartons—maximizing storage density, speeding retrieval, and enabling seamless multi-floor warehouse operations.

Our Detailed Deliverables

- Vertical Lift Modules (VLMs) for automated storage & retrieval

- Vertical conveyors for inter-floor transport

- Load transfer systems at each level

- Safety interlocks for operator protection

- Multi-floor control system

How It Works

- Order triggers retrieval from storage level

- WMS sends instructions to VLM/lift

- System retrieves item and loads conveyor

- Conveyor moves item to required floor

- Transfer system places item onto floor conveyor

- Item continues to picking/packing

- Inventory updated in real time

Key Customer Benefits

- 300%+ better storage utilization

- Fast, automated item retrieval

- High picking accuracy at ergonomic height

- Smooth multi-floor material flow

- Reduced worker strain

Industries We Serve

FMCG, Manufacturing, Retail Distribution, 3PL/4PL, E-commerce

Variants We Offer

- Basic EOL – Manual packing + automated labeling

- Standard EOL – Automated packing, labeling & palletizing

- Advanced EOL – Full robotics + AI quality verification

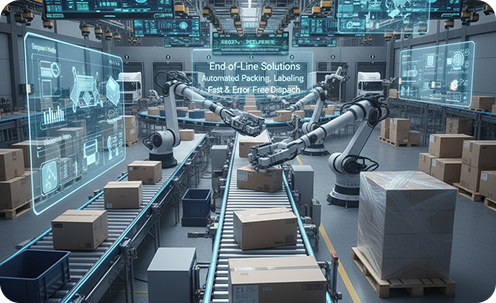

End-of-Line Solutions

Automated packing, labeling, palletizing, and wrapping—ensuring fast, consistent, and error-free dispatch preparation for every shipment.

Our Detailed Deliverables

- Automated case packers

- Print & apply labeling systems

- Robotic palletizers

- Stretch wrapping machines

- Dimensioning systems

- Shipping system integration

How It Works

- Completed orders reach packing station

- Case packer arranges items

- Labels printed & applied automatically

- Dimensions captured for optimization

- Palletizer builds stable pallet loads

- Stretch wrapper secures the load

- Shipping documents generated automatically

Key Customer Benefits

- Consistent, spec-accurate packing

- 20+ cases/min high-speed processing

- Reduced packaging & freight costs

- Zero labeling/packing errors

- Damage-free, secured loads

Industries We Serve

E-commerce, 3PL/4PL, FMCG, Retail, Manufacturing

Variants We Offer

- Portable Telescopic – Mobile, multi-dock use

- Fixed Telescopic – solution for high-volume doors

- Gravity Roller System – Budget-friendly, non-powered

Loading Dock Conveyors

Telescopic and fixed conveyors that connect warehouse to truck—speeding loading/unloading, reducing manual labor, and improving overall dock safety.

Our Detailed Deliverables

- Telescopic conveyors for trailer reach

- Fixed dock conveyors for high-volume docks

- Height-adjustable systems

- Safety sensors for accident prevention

- Dock levelers for gap bridging

- Control panels for safe operation

How It Works

- Truck docks and secures position

- Dock leveler bridges the gap

- System adjusts to truck bed height

- Telescopic conveyor extends inside trailer

- Items flow automatically between warehouse & truck

- Operator supervises safety and movement

- Conveyor retracts after completions

Key Customer Benefits

- Load/unload 3× faster

- Minimal manual handling

- Reduced injuries & safer operations

- Fits multiple truck sizes

- Lower labor and compensation costs

Industries We Serve

E-commerce, 3PL/4PL, Parcel & Courier, Pharmaceuticals, High-Value Goods

Variants We Offer

- Label Verification – Basic label + barcode checks

- Quality Inspection – Adds damage & orientation checks

- Advanced AI – Full anomaly detection

Auto Dispatch Verification

AI-powered inspection of labels, counts, orientation, and package quality—eliminating shipping errors and ensuring complete traceability for every dispatch.

Our Detailed Deliverables

- AI vision cameras

- Machine learning detection models

- OCR & barcode verification

- Quantity/count verification system

- Alert & rejection mechanism

- Traceability database for shipment records

How It Works

- Packed items pass through AI inspection tunnel

- Multi-angle cameras capture package images

- Labels validated via OCR/barcode reading

- System verifies package counts

- Orientation accuracy checked

- Damage/defect detection performed

- All data logged with image records

Key Customer Benefits

- 99.9%+ error prevention

- Photo-proof documentation

- Accurate quantity verification

- Full shipment traceability

- Reduced returns & claims

Qualicom: Crafting Components For Critical Applications

Why Choose Us

The Qualicom Automation?

Experience transformative benefits that drive measurable ROI and competitive advantage.

Increased Productivity

Boost output by 40–60% with continuous, consistent 24/7 automated operation.

Reduced Operating Costs

Cut labor, minimize scrap, and optimize resources for faster ROI.

Enhanced Quality Control

Achieve 99.8%+ accuracy with automated inspection and real-time monitoring.

Improved Safety

Keep workers away from hazardous tasks with fully automated handling.

How We Deploy

Technologies We Deploy

Who We Serve

Industries We Serve

delivering solutions trusted by high-performance industries.

Ecommerce

FMCG

Parcel & Courier

3PL/4PL

Retail Distribution