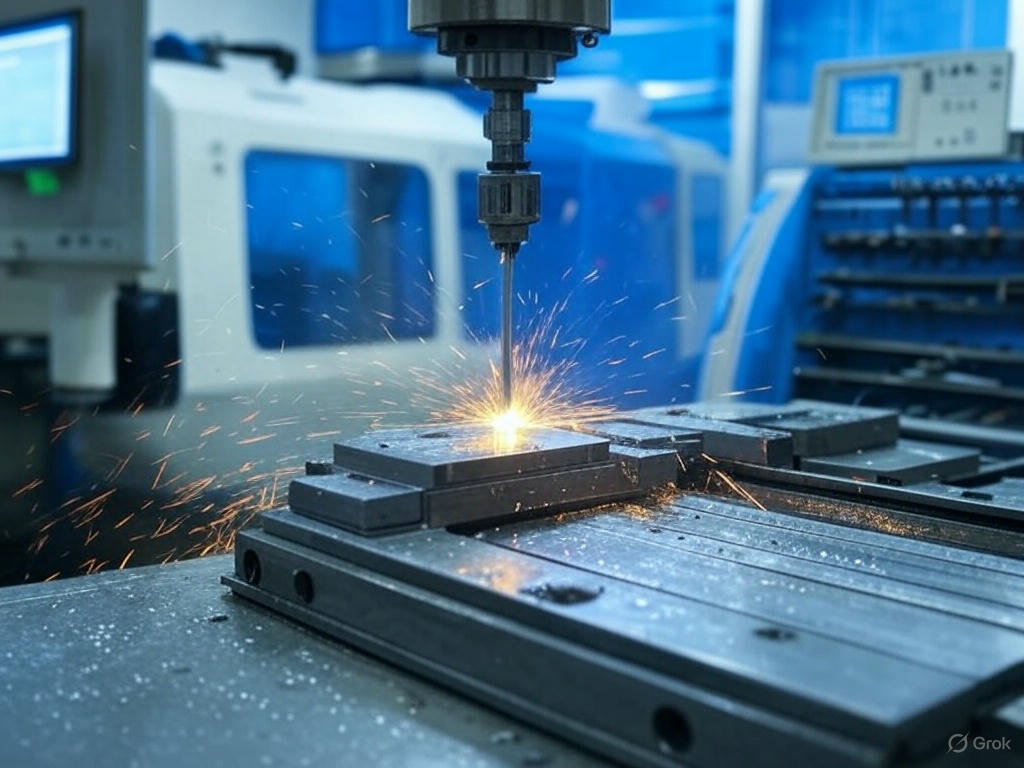

How to Optimize CNC Machining for Maximum Efficiency?

CNC machining is the backbone of modern manufacturing, but efficiency isn’t just about running machines faster—it’s about working smarter. Whether you’re handling high-precision components or large production runs, fine-tuning your CNC operations can make all the difference in cost savings, quality, and turnaround time. Here’s how you can maximize efficiency in your shop floor without cutting corners.

1. Get Your Cutting Parameters Right

Ever heard the saying, “Garbage in, garbage out?” The same applies to CNC machining. Running a job at the wrong cutting speed, feed rate, or depth of cut can wreck tool life and compromise part quality. Instead of relying on guesswork, use manufacturer-recommended values and tweak them based on real-time performance. If you’re not experimenting with high-speed machining (HSM), you’re leaving efficiency on the table.

2. Invest in the Right Tooling (and Take Care of It!)

Quality tooling isn’t just a luxury—it’s a necessity. The right tool can shave minutes off cycle times and drastically reduce downtime. Here’s what to look out for:

- Carbide vs. HSS Tools: Carbide tools handle higher speeds and last longer, making them ideal for tough jobs.

- Coatings Matter: TiN, TiAlN, and DLC coatings can reduce wear and improve tool life.

- Geometry Counts: The right flute count and helix angle ensure smoother cutting and better chip evacuation.

And don’t forget—regular tool maintenance, regrinding, and timely replacements keep production running smoothly.

3. Smarter Programming = Faster Machining

Your CNC machine is only as smart as the code you feed it.

- Optimized Toolpaths: Reduce unnecessary movements with efficient CAM programming.

- Adaptive Machining Strategies: Trochoidal milling, for example, reduces tool stress and improves material removal rates.

- Minimize Air Cuts: If your machine spends more time moving than cutting, you’re losing money.

A few extra minutes spent refining the program can save hours on the shop floor.

4. Embrace Automation & Smart Manufacturing

If you’re still relying on manual loading and setups, it’s time to step up. Robotic loaders, pallet changers, and tool presetters can slash downtime and boost efficiency. Plus, real-time machine monitoring and predictive maintenance mean fewer surprises and more consistent output.

5. Fix Your Fixtures

An unstable workholding setup can introduce vibration, misalignment, and wasted time. Consider these options:

- Modular Fixtures: Reduce setup time between jobs.

- Vacuum or Magnetic Workholding: Great for thin-walled parts that are tricky to clamp.

- 5-Axis Workholding: Cuts down on multiple setups, improving accuracy and efficiency.

6. Cut Setup Time in Half

- Standardized Tool Libraries: Reduce confusion and speed up setup times.

- Pre-Set Tools: Setting tools outside the machine saves valuable production hours.

- Automated Tool Changers: Helps in switching tools seamlessly during machining operations.

Small tweaks in the setup process can lead to massive efficiency gains over time.

7. Monitor OEE & Shop Floor Performance

If you’re not tracking Overall Equipment Effectiveness (OEE), you’re missing out on valuable insights. Keeping an eye on availability, performance, and quality metrics helps identify bottlenecks and inefficiencies. The more real-time data you collect, the better decisions you can make.

8. Train Your Team & Improve Workflow

A machine is only as good as the person operating it. Regular training keeps your team updated with the latest machining techniques and best practices. Additionally, optimizing the shop floor layout minimizes unnecessary movement and streamlines operations.

9. Prioritize Machine Maintenance

Skipping maintenance is like skipping oil changes in your car—it’ll catch up with you. Regular inspections, lubrication, and alignment checks help prevent breakdowns and keep machines running at peak performance.

10. Reduce Scrap & Rework

Scrap and rework don’t just waste material; they eat into your profits. Automated probing systems and high-precision measuring tools ensure parts meet specifications the first time around. The goal is to catch errors before they turn into costly mistakes.

Conclusion

Optimizing CNC machining efficiency isn’t about taking shortcuts—it’s about refining every step of the process. From fine-tuning cutting parameters to embracing automation and improving workflow, small changes add up to big gains. By focusing on efficiency, manufacturers can boost productivity, lower costs, and stay ahead of the competition.

At Qualicom, we’re always pushing the boundaries of machining efficiency. Want to learn more about how we achieve precision and productivity? Get in touch with us today- contact@qualicom.in